| Why is dealing with manual handling important?

Manual handling injuries can have serious implications for the employer and the person who has been injured. They can occur almost anywhere in the workplace and heavy manual labour, awkward postures, repetitive movements of arms, legs and back or previous/existing injury can increase the risk. Across the organisation we have had a few incidents relating to manual handling so it is important that we firstly try to avoid manual handling, if it can’t be avoided we assess the risk of injury from any hazardous manual handling; and reduce the risk of this injury, so far as is reasonably practicable.

What Is my role and responsibility? To help prevent manual handling injuries in the workplace, you should avoid such tasks as far as possible. However, where it is not possible to avoid handling a load, managers must look at the risks of that task and put sensible health and safety measures in place to prevent and avoid injury. Reduce the risk of injury from hazardous manual handling, (so far as is reasonably practicable) and lift correctly to avoid injury. Consider the use of equipment to remove the hazard to staff or look to engage competent contractors to carry out the lift for you. What should I asses for a lifting activity? When you think of manual handling think of LITE. Think about : · Load and its nature · Individual capability · Training · Environmental conditions · And finally think about the organisation of the work. Plan the works carefully. It is important to know your limits with certain lifting tasks and to draw on the knowledge and expertise of others (such as engaging specialist competent contractors) where task may be more complex. This should be communicated to all staff (with a written record).

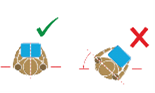

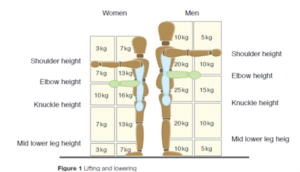

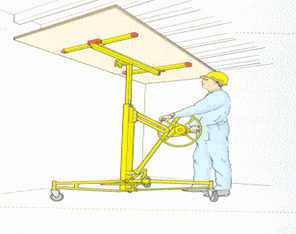

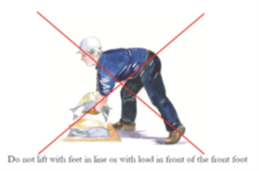

What if I need to lift of move something manually? · Reduce the amount of twisting, stooping and reaching · Avoid lifting from floor level or above shoulder height, especially heavy loads · Adjust storage areas to minimise the need to carry out such movements · Consider how you can minimise carrying distances · Assess the weight to be carried and whether the worker can move the load safely or needs any help maybe the load can be broken down to smaller, lighter components What if I need to use lifting equipment? · Consider whether you can use a lifting aid, such as a forklift truck, electric or hand-powered hoist, or a conveyor. Please note for larger items such as safes or large complex items, these need to be outsourced to competent contractors to reduce the risk to Bron Afon staff. · Think about storage as part of the delivery process – maybe heavy items could be delivered directly, or closer, to the storage area · Reduce carrying distances where possible · Make sure staff are competent and trained in the safe use of the equipment. Please note that the equipment and lift may also need to meet certain requirements under the Lifting Operations and Lifting Equipment Regulations (LOLER) What should I consider before attempting to move items? There are some simple things to do before and during the lift/carry: · Remove obstructions from the route. · For a long lift, plan to rest the load midway on a table or bench to change grip. · Keep the load close to the waist. The load should be kept close to the body for as long as possible while lifting. · Keep the heaviest side of the load next to the body. · Adopt a stable position and make sure your feet are apart, with one leg slightly forward to maintain balance Think before lifting/handling Plan the lift. Can handling aids be used? Where is the load going to be placed? Will help be needed with the load? Remove obstructions such as discarded wrapping materials. For a long lift, consider resting the load midway on a table or bench to change grip. Adopt a stable position The feet should be apart with one leg slightly forward to maintain balance (alongside the load, if it is on the ground). Be prepared to move your feet during the lift to maintain your stability. Avoid tight clothing or unsuitable footwear, which may make this difficult. Get a good hold Where possible, the load should be hugged as close as possible to the body. This may be better than gripping it tightly with hands only. Start in a good posture At the start of the lift, slight bending of the back, hips and knees is preferable to fully flexing the back (stooping) or fully flexing the hips and knees (squatting). Don’t flex the back any further while lifting

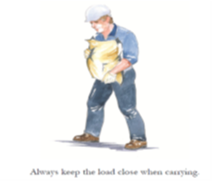

This can happen if the legs begin to straighten before starting to raise the load. Keep the load close to the waist

Keep the load close to the body for as long as possible while lifting. Keep the heaviest side of the load next to the body. If a close approach to the load is not possible, try to slide it towards the body before attempting to lift it. Avoid twisting the back or leaning sideways, especially while the back is bent

Shoulders should be kept level and facing in the same direction as the hips. Turning by moving the feet is better than twisting and lifting at the same time. Keep the head up when handling Look ahead, not down at the load, once it has been held securely. Move smoothly

The load should not be jerked or snatched as this can make it harder to keep control and can increase the risk of injury. Don’t lift or handle more than can be easily managed There is a difference between what people can lift and what they can safely lift. If in doubt, do not attempt the lift, seek advice or get help. Put down, then adjust If precise positioning of the load is necessary, put it down first, then slide it into the desired position.

Guidance on weights

Guidance for Manual Handling on Construction Sites

When you have to manually handle loads consider: · Load and its nature · Individual capability · Training · Environmental conditions

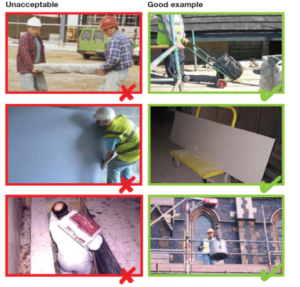

Some examples of hazards • General Handling • Large of heavy Building Blocks • Panel products e.g. Plasterboard • Heavy Lintels • Bagged Aggregate

Simple Aids on Site

Masonry Blocks • Specify/order blocks that weigh less than 20kg • Store blocks where they will not get wet (and increase their weight) • Arrange work so that lifting over shoulder height is not carried out • Deliver blocks as close to the point of laying as possible • Do not carry them up ladders • Raise spot boards to a comfortable working height • Adjust scaffold platform to be at a height to allow the bricklayer to work between their knees and chest (if hop up used make sure that edge protection is provided on the main scaffold that takes account of this

Panel products e.g. Plasterboard • Much more difficult to manoeuvre (and risky) in windy conditions • 8’x4’ boards of 15mm thickness are all over 25kg and some ‘special’ boards can be up to 50kg • It is possible to select smaller boards which are lighter and more manoeuvrable • Don’t remove handrails/banisters to move boards up stairs as this creates a fall risk • Use aids to hold and position boards

Heavy Lintels • Use mechanical aids such as lift trucks etc • An alternative is to specify lightweight steel lintels where possible. • Order materials in smaller unit weights (max. 25kg) so that they can be more easily handled….OR • Order the materials in such large unit weights that they can only be handled mechanically. Hazardous Manual Handling

• Do not try to manually handle items that weigh over 100kg • Do not try to use manual handling teams of more than 4 people.

General Tips · Plan and prepare for deliveries • Find out how much commonly used items weigh • Use simple aids • Do not try to handle items heavier than 100kg or use teams of more than 4 people HSE Website : http://www.hse.gov.uk/msd/ and http://www.hse.gov.uk/pubns/indg398.pdf Bron Afon Manual Handling Procedure Bron Afon Safety Briefing Note : Making the best use of lifting and handling aids

|

|||||

- Home

- Knowledge Base

- Work safe

- Safety Briefing – Moving, Lifting and Handling (Manual Handling)