1.0 What do Managers/Supervisors need to do?

- Follow the responsibilities noted in the Working at Height Procedure

- Make sure those involved in ladder work are competent

- Ensure the risks from the work have been assessed and identify the safest work method when using a ladder and appropriate work equipment is selected and used

- Formally inspect and maintain the ladders in line with regulations and manufacturers requirements

- Ensure all ladders are asset tagged and a register kept

- Ensure equipment that is hired has been inspected

- Ensure the risks from work on scaffold are assessed and appropriate work equipment is selected and used

- An emergency rescue plan is included within the risk assessment and communicated to the team

- Equipment for work at height is properly inspected and maintained

- Ensure that prevention of authorised public access is assessed and any possible access routes have suitable controls in place (e.g. ground floor ladders to scaffolding are removed when not in use)

2.0 What do all staff working on ladders need to do?

- Follow the responsibilities noted in the Working at Height Procedure

- Safeguard their own safety and health and that of others who may be affected by their actions or inactions

- Complete pre-user checks

- Present ladders for asset tagging and formal inspection. Do not use if ladder does not have asset tag or has no formal inspection carried out within 3 months

- Check the equipment is in a good condition and being used safely by using the pre-use checklists

- Use ladder in accordance with the safe systems in place and training

- Report any hazards, unsafe situations or equipment immediately to their line manager

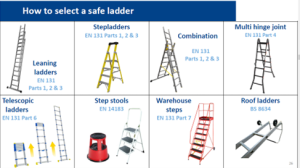

3.0 What ladders should be used?

Ensure the ladders selected are suitable for work use and are designated Class 1 or EN1314 in the old system. New ladders supplied since 1st Jan 2019 are now classed as EN131 Professional and EN131 non-professional. EN 131 Professional is the equivalent of the old Class 1 standard. Choose a certified ladder e.g. kitemarked

EN131 Non Professional (old Class 3) ladders and stepladders are for domestic use only and must not be used in the workplace.

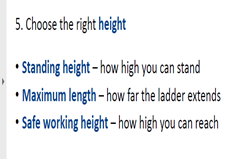

Selecting the right equipment is essential. The HSE has provided a helpful step by step guide to control the risk of working at height.

Step-by-step guide to control risk of work at height – HSE

The law says that ladders can be used for work at height when an assessment of the risk for carrying out a task has shown that using equipment offering a higher level of fall protection is not justified because of the low risk and short duration of use, or there are existing workplace features which cannot be altered. Short duration is not the deciding factor in establishing whether use of a ladder is acceptable. You must have first considered risk. As a guide, if your task would require staying up a leaning ladder or stepladder for more than 30 minutes at a time, it is recommended you use alternative equipment. You should only use ladders in situations where they can be used safely, eg where the ladder will be level and stable, and can be secured (where it is reasonably practicable to do so).

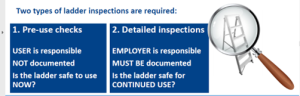

4.0 What inspections need to be carried out?

Ladders and step ladders must be in good, safe condition and subject to a visual check prior to use, it shall be the responsibility of each user to check the safety before usage. Users are to advise the ladder owner or line manager if they consider that equipment is not safe to use.

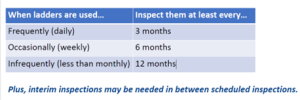

Formal Detailed inspections should be carried out as below :

- Ladders that are subject to frequent use (on a daily basis) should be inspected at least once every 3 months*

- Ladders that are subject to occasional use (on a weekly basis) should be inspected at least once every 6 months*

- Ladders that are subject to infrequent use (in excess of monthly) should be inspected at least once every 12 months

*Frequency of these inspections should always be in accordance with manufacturer’s instructions. Checks should be logged on a Ladder Register and records retained. Any new ladders should also be checked prior to first usage.

If ladders are damaged or unfit they should be marked as unfit, withdrawn from use and returned for recycling or repair.

Pre-Use Checks

Prior to undertaking any work from a ladder or step ladder for the first time the user is required to undertake a pre use check. The other requirement is for detailed visual inspections which should be recorded. Pre use checks and detailed visual inspections are both looking for obvious visual defects, they only differ in detail. Both can be done in-house (pre use checks should be part of a user’s training).

A pre use check should be carried out by the user; at the beginning of the working day; and after something has changed i.e. ladder dropped or moved from a dirty area to a clean area. The benefit of conducting daily pre use checks is that they provide the opportunity to pick up any immediate/serious defects before they cause an accident.

Do pre-use checks

- At the beginning of the working day; and

- After something has changed, for example:

- The ladder is dropped

- Left unattended

- Transported on a vehicle

- Moved from a dirty area to clean area

- Check the feet

- Check the stiles

- Check locking mechanisms and so on…

Spot a defect? Do NOT use the ladder! Isolate, tag, report to Supervisor

Formal detailed inspections should be carried out as detailed above by the relevant Supervisors

5.0 Safe use Ladders

DO

- Use only issued equipment with an asset number/inspection record

If the equipment does not have this – do not use!!

- Use the ladder in accordance to your training

- Use for short duration work (maximum 30 minutes) and Light work (up to 10 kg)

- Visually check the equipment is a good condition and being used safely by using the pre-use checklist (including ladder stabiliser where fitted)

- Check all rubber feet are in situ

- Use good grip gloves to help prevent from slipping through your hands when putting into position

- Stand the ladder on a firm level base and not on loose material at locations where there will be no danger of being struck by passing vehicles or equipment.

- Set the ladder at the correct angle – 1 out to every 4 up angle 75º In other words, the horizontal distance from the base of the ladder to the supporting surface shall not be greater than one-quarter of the ladder length

- Check maximum safe ground side slope (level the rungs with a suitable device)

- Check maximum safe ground back slope

- Have a strong upper resting point (not plastic guttering)

- Tops of ladders being used for ascending scaffolding or other solid platforms should extend 92 to 107cm above the top landing in order that workers getting on or off will have a solid handhold

- Solidly decked landing should be provided at the top of all ladders being used for ascending scaffolding or other solid platforms. When cleats extend to the top of the side rails, landing platforms at least 76cm wide should be built out from the floor to extend to a minimum of 51cm beyond the outer edge of the side rails. Guard- rails and toe-boards should be erected on the outer end and the exposed side of the platform

- Secure ladders at both top and bottom. At the top, nail the ladder or lash it with wire or rope to a secure object. At the bottom, secure it against movement by blocking, tying or other suitable method

- If this is impracticable, see that it is firmly secured at the base.

- Always grip the ladder when climbing

- Make sure footwear is in good condition

- Make sure you clean wet, icy or greasy rungs before use

- Make sure you clean off mud or grease from boots before climbing Always grip the ladder when climbing

- Make sure you carry light tools in a holster or a tool bag slung from a strap over the shoulder, or use a hoist line

- Do not lean sideways

- Don’t throw things from ladders

- DON’T work above the top three rungs – as this provides a handhold

- NEVER stand on the top step with no handrail

- Remember-three points of contact at all times when on the ladder

- Report any defects or unsafe situations to your supervisor/line manager

DO NOT

- Use a make-shift ladder, domestic ladder or one that has not been supplied through Travis Perkins

- Use a ladder that is too short

- Stand a ladder on a drum, box or other unsteady base

- Allow more than one person on a ladder at a time

- Overreach from a ladder; move it to a more advantageous position

- Use metal or metal reinforced ladders near electricity cables

- Use ladders with cracked or broken rungs or other defects

- Do not overreach – make sure your belt buckle (navel) stays within the stiles and keep both feet on the same rung or step throughout the task

- Do not work off the top three rungs – this provides a handhold

- Leave ladders unattended when not in use

- Do not leave ladder access to scaffold from ground level unattended

- Do not carry out any repairs to your ladder – advise your Supervisor of defect

6.0 Safe use of Stepladders

DO

- Only use a stepladder with an asset number/inspection record

- Carry out daily pre-use check (feet included)

- Ensure there is space to fully open

- Use any locking devices

- Make sure ground should be firm and level

- Make sure Floors should be clean, not slippery

- Use for short duration work (maximum 30 minutes) and Light work (up to 10 kg)

- Report any defects or unsafe situations to your supervisor/line manager

DO NOT

- Work off the top two steps (top three steps for swing-back/double-sided stepladders) unless you have a safe handhold on the steps

- Carry out side-on working

- Overreach – make sure your belt buckle (navel) stays within the stiles and keep both feet on the same rung or step throughout the task

7.0 Safe use of Roof Ladders

HSE advise Roof Ladders may be used providing more suitable equipment cannot be used, because ladders are a last resort and should only be used for low risk, short duration work.

It is also worth considering that there are alternatives to roof ladders as a form of roof access. Ladder staging systems work in conjunction with roof ladders to create a roof platform for safe roof access

The roofing ladder classification specific to roof ladders is BS 8634:2017, but most roof ladders should comply with the EN 131 professional standard or the Class 1 standard. If using a roof hook kit then the ladder that you attach the roof hook to will be classified to at least a BS EN 131 professional or a Class 1 ladder, kitemarked i.e. with a BS standard as required.

On most sloping roofs, suitable roof ladders or crawling boards will be essential, in addition to edge protection. Where a high standard of edge protection is provided, it may be safe to work without a roof ladder. This may apply if the pitch is shallow and the surface provides particularly good foothold and is non-fragile. In each case the decision should be based on a site specific risk assessment.

Roof ladders or crawling boards should be :

- designed and fabricated to be fit for purpose

- strong enough to support workers when spanning across the supports for the roof covering;

- long enough to span the supports (at least three rafters); and

- secured or placed to prevent accidental movement

The anchorage at the top of the roof ladder should be by some method which does not depend on the ridge capping as this is liable to break away from the ridge. The anchorage should bear on the opposite slope by a properly designed and manufactured ridge hook (see Figure 29) or be secured by other means.

Where ladders are used, they need to be :

- Risk assess the requirement for using this type of ladder

- Only used by staff trained in their use

- of an industrial grade, in good condition

- Secured to prevent movement

- The anchorage at the top of the roof ladder should be by some method which does not depend on the ridge capping, as this is liable to break away from the ridge.

- The anchorage should bear on the opposite slope by a properly designed and manufactured ridge hook or be secured by other means

- Report any defects or unsafe situations to your supervisor/line manager

Do not

- Do not use roof ladders that have not been inspected, asset tagged etc.

- Do not leave ladders unattended when not in use

- Do not use if you have not been trained in safe use

- Do not use if the necessary controls identified on the risk assessment are not in place

8.0 Safe use of Hop ups or Trestles

Hop ups are safe in certain circumstances but Low level platforms or hop ups or trestles, do provide limited height and a lack of support in comparison to other types of access equipment. While durable, they should only be used for low-level access. If they don’t quite give you the height required, and you need to overreach, another product such as a stepladder should be used.

If the work you’re doing involves having to reach, use tools and equipment, or potentially be unsteady, a podium or work platform with rails should be considered. Not only are they more comfortable to work from for long periods of time, they also significantly reduce the risk of injury when working at a height.

Hop ups should always be used in accordance to the weight requirement of the user.

- Hop up platforms will be properly constructed in accordance with British and European Standards, manufacturer’s instructions and current legislation

- The dimensions form and layout of working platforms shall be appropriate to the nature of the work to be performed

- Hop ups must be founded on a firm and level surface

- Hop up platforms will not be overloaded

- All Hop ups will be inspected by a competent person before use to ensure all parts of the equipment are in good condition and suitable for intended use

- Pre use checks to be carried out prior to use, any faults found are to be reported immediately and the equipment taken out of use

Remember!

9.0 Further HSE Guidance

- The Work at Height Regulations – a brief guide, HSE Books Work at height – Occupational health and safety – HSE

- Using Ladders Safely – Work at height – Using ladders safely (hse.gov.uk)

- Safe Use of Ladders and Stepladders A brief guide HSE and Ladder Association LA455

- HSE Height Aware – Selecting equipment for work at height

- HSE Height Aware – Selecting, using and maintaining personal fall protection equipment

- HSE Construction Information Sheet No 10, Tower Scaffolds

- HSE Information Sheet MISC 614, Preventing falls from boom-type mobile elevating work platforms.

- HSE Height Aware – Safe use of ladders and stepladders – an employers’ guide” Ref INDG402.

- HSE Height Aware – Absolutely Height Safe – Essential health and safety information for people who work at height (PDF – 312 KB, external site)

Ladder Inspection Checklist

|

| Classification | Duty Rating | Maximum Static Vertical Load | Symbol |

| BS / EN 131 Professional

Trade use |

150Kg |

175Kg |

|

| BS / EN 131 Non-Professional Domestic DIY use |

150Kg |

150Kg |

|

| Department Name | |

| Inspection date: | |

| Ladder description: | |

| Identification reference: | |

| Name of person checking: | |

| Signature: |

|

| Item Checked | Condition | Comments | |

| OK | Faulty | ||

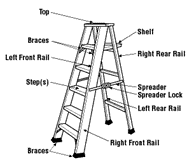

| Stiles | |||

| Damaged or bent | |||

| cracked, split, twisted or distorted | |||

| free from over wear | |||

| free from grease, mud, paint, etc. | |||

| feet present and in good condition | |||

| Label visible and readable | |||

| EN131 Professional (or class 1) specification | |||

| Rungs/Treads | |||

| Bent, cracked or split, | |||

| twisted or distorted | |||

| free from over wear | |||

| Loose (can they be moved by hand?) | |||

| Loose screws or bolts (can they be moved by hand?) | |||

| Stabiliser present or missing | |||

| Ladder Fittings/Rivets/Welding | |||

| all intact | |||

| free from decay or corrosion | |||

| tie rods secure | |||

| distortion free (ladder stands correctly) | |||

| Defective hinges | |||

| Rung locks, Loose, bent, missing or broken | |||

| Defective ropes or pulleys | |||

| Loose mounting brackets | |||

| Stop on spreaders broken | |||

| Defective centre guide for extension | |||

| Other | OK | Faulty | Comments |

| For Telescopic ladders – Are all locks functional and operating correctly? | |||

| Is ladder stable when fully extended? | |||

| Any items not listed above

|

|||

| any unofficial repairs | |||

| ladders of suitable standard /classification | |||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||